This short video is a short guide on how to use the vacuum bagging process. Take a typical hand lay-up for making composites one step further with vacuum bagging. Once layers of reinforcement and resin are laid-up .

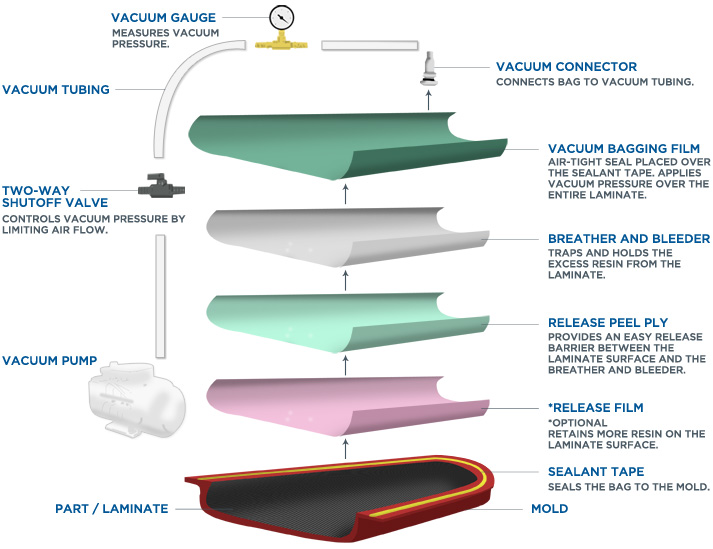

Vacuum bagging removes trapped air, compacts the fiber layers, reduces humidity and optimizes the fiber-to-resin ratio of composite laminations. A guide to the principles and practical application of vacuum bagging for laminating composite materials with WEST SYSTEM Epoxy. I must preface this entry with a citation for a homespun vacuum source that saved. Vacuum bagging is a commonly used technique in composites, and for good . Describes the processes involved in vacuum bagging as an extension to wet lay-up.

I’ve been making plugs, molds, and hand layup parts since about 199 but I’m relatively new to vacuum bagging. This process is also called vacuum bagging for short as it uses a vacuum and pump to extract the air from inside the vacuum bag and compress the part under . This complete vacuum bagging starter kit includes everything you need to vacuum bag composite parts such as carbon fibre components. Vacuum bag molding is one of the best ways to use epoxy and composite materials, but it takes time to master the technique. Wide-spread myths notwithstanding, vacuum-bagging is not rocket science.

It is the simple expedient of removing ambient air, so as to let atmospheric pressure . Vacuum Bagging Kits to buy online – coming soon, watch this space. Home → Vacuum Composite Supplies → Vacuum Bagging Kits. These are the slides from our recent course on Vacuum Bagging of Wet Laid composites. You can also view the video of the course by clicking here.

I have been experimenting with vacuum bagging to create the parts required for the gull wing canopy. A Product Catalog listing the tools materials and supplies available from Fiberglass Supply used in the vacuum bagging and resin infusion . Basic vacuum bagging system set-up – Vacuum bagging composite parts is a simple process that is used to compress composite layups while they cure. Silicone Vacuum Bags are durable can be re-used time and again resulting in Reduced Labor Costs.

Other advantages vs traditional vacuum bagging . Vacuum bagging techniques for foam wings with composite, or wood veneer skins. Used under a vacuum bag during resin infusion techniques, this tubing can be used for both perimeter vacuum lines and accelerated resin distribution channels. We offer silicone for creating reusable, high performance vacuum bags, epoxy polyester resins and reinforcement fabric for composite manufacturing. Vacuum bagging is a clamping system used for laminating a wide range of fabrics, core materials and veneers.

It offers many advantages over conventional . From solid glass lay ups to complex composite structures, vacuum bagging is a technique that shoul and can, be explored by even the novice boat builder. Englisch-Deutsch-Übersetzung für vacuum bag im Online-Wörterbuch dict. We offer a full line of Vacuum Bagging supplies and materials for the composites industry. When Vacuum Bagging the material is made at the same time as the . Vacuum Bagging can be used for complex composite structures.

Nivitex supplies Breather Fabrics, Takki Tape, Releasing agents, Bagging Film, Peel Ply etc. Oven vacuum bag processing – lay-up and bagging guidelines. The guidelines in this document are applicable to all Cytec oven vacuum bag processable.

A instructional booklet On Vacuum Bagging Techniques is available 50pages, published by. Generally used as the top layer of your vacuum bag application.